The collaboration between Came and customer has made an ambitious class IE3 efficiency improvement project possible.

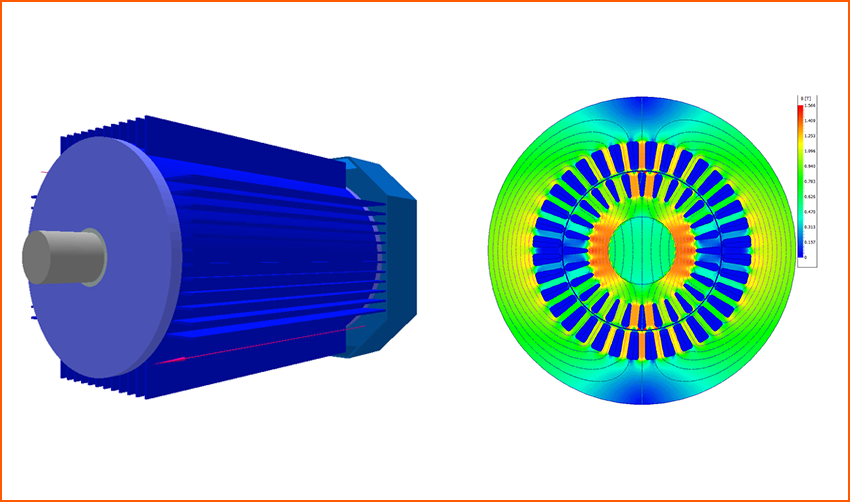

One of our customers needed to upgrade their range of cast iron motors to efficiency class IE3, while leaving the normalised casing diameter unchanged. The main challenge lay in the lower capacity of cast iron to dissipate heat compared to aluminium, making it difficult to achieve the required efficiency without changing the motor size.

The project stages

1) Co-design with the customer: we worked closely together to understand the specific needs and design constraints.

2) Lean planning: we structured the project with a detailed Gantt chart, adopting a lean approach to optimise time and resources.

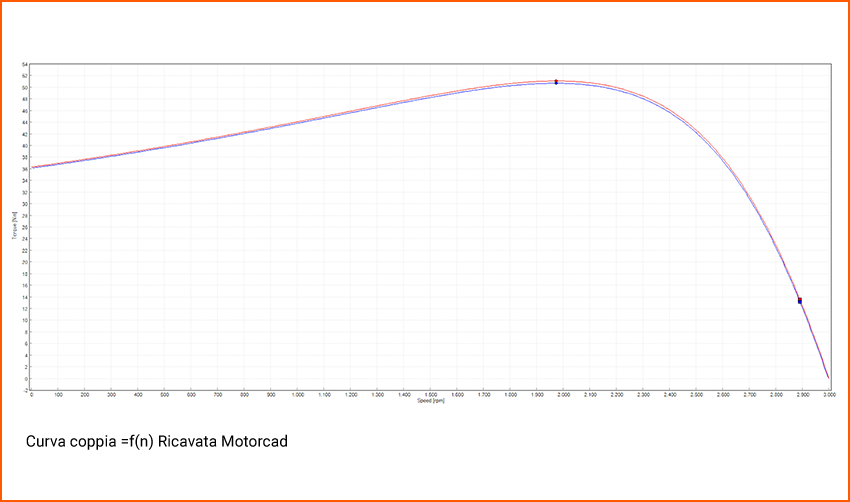

3) Dimensioning with Motor-CAD: we used the Motor-CAD software to simulate and optimise the electrical performance of the motor, considering the design constraints.

4) In-house production in Came: the production stages – excluding assembly and construction of the rotor shafts – were managed in-house to ensure full control over quality and delivery times.

5) Delivery of the coded IE3 report: we tested the motor to standard 60034-2-1 in our laboratory, and provided the customer with a report in accordance with Annex D of the same standard to aid motor approval.

The results we obtained

– IE3 efficiency achieved: we obtained the required efficiency without altering the outside dimensions of the motor.

– Reduction of inrush currents (ICC): optimisation led to a decrease in ICC, thus aligning performance with the standard required by the relevant market.

– Efficiency increase of up to 8% compared to an IE1 motor: the new design offered a significant energy efficiency improvement and consequently a lower operating temperature, as well as lower running noise as some mechanical components were revised.

Conclusions

This project demonstrates how a close collaboration between the Came team and the customer, combined with the use of advanced tools such as Motor-CAD, makes it possible to overcome technical challenges and achieve ambitious energy efficiency improvement targets, even when there are stringent design constraints.