Die-casting and mechanical machining of castings can be defined as two of the most common processes in metal part manufacturing. It is important to know, however, that in order to optimize the result of a machined die casting, it is necessary to integrate the two processes right from the component design.

For this reason, today we will give you some key concepts to understand when machining is necessary and what precautions are required on the raw casting to accommodate the processing.

First of all, I would like to start by giving a brief description of the two processes:

– Die-casting: the molten aluminium alloy is injected under pressure into a special mold, which gives the casting the shape of the part to be made once the alloy inside has cooled.

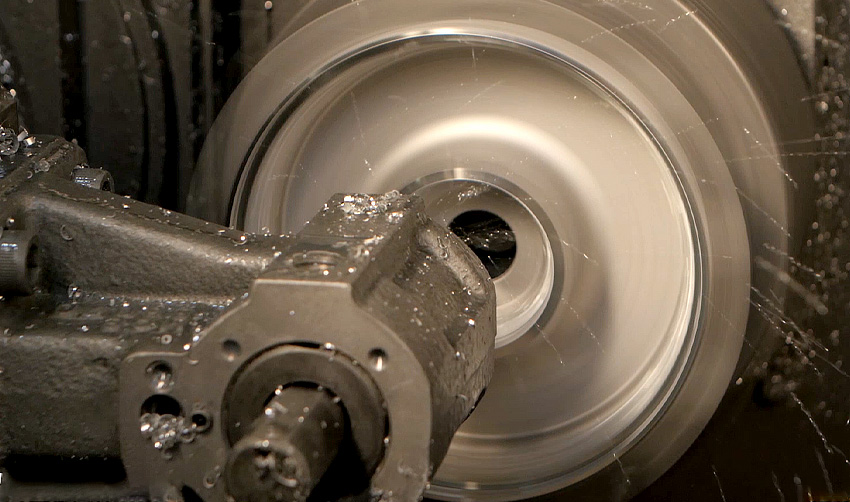

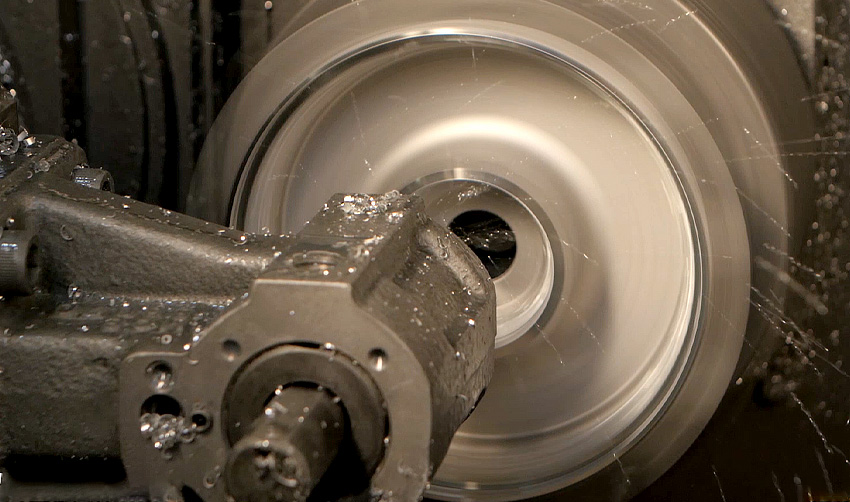

– Mechanical machining: this is a process that alters the shape and characteristics of the material by removing chips with speed and versatility, following all the indications prescribed by a drawing.

The use of CNC technology (computer numerical control) and special tools makes it possible to maximize the processing precision, repeatability and efficiency.

In the die-casting sector, CNC machining is used to modify die-cast parts and produce features that cannot be produced in the die-casting mold. This allows us to customize parts based on specific customer needs and to send ready-to-install parts.

For example, it is possible to use processing on a die-cast part to:

– Obtain tighter tolerances;

– Improve surface roughness;

– Deep holes;

– Corners without radius.

Numerical control processing can also be useful to remove edges and draft angles, often necessary to complete high pressure die-casting processes or to create special shapes that cannot be obtained from a mold (under cuts).

Furthermore, processing can be useful to simplify the die-casting mold, thereby making it more economical. Specifically, it is possible to decide to obtain some features on the casting (radial holes) directly by mechanical drilling. This avoids the need for lateral movements on the mold (larger mold dimensions, longer cycle time, larger press, and higher equipment cost).

The degree of processing required can vary significantly from one product to another. For example, less complex parts may require drilling or threading only, which can often be done without CNC machining services but with a simple manual unit off the work island. On the other hand, complex components with special designs or with demanding mechanical characteristics (automotive components, components subject to mechanical seals, etc. ) require high-precision machining that can be achieved through the CNC machining process.

Came has a vast fleet of machines that includes both manual units dedicated to drilling and threading, and CNC machines (lathes, milling machines, 4- or 5-axis multi-pallets) useful for performing complex machining with maximum process speed and repeatability.

The Came R&D office can also support you in determining which type of manufacturing process is most appropriate for your products and can guide you through the component design phase to optimize the raw casting and the processes required to obtain the finished component, optimizing the workflow and consequently the final price.

Contacts

consulting@came-italy.com

+39 0444 488282